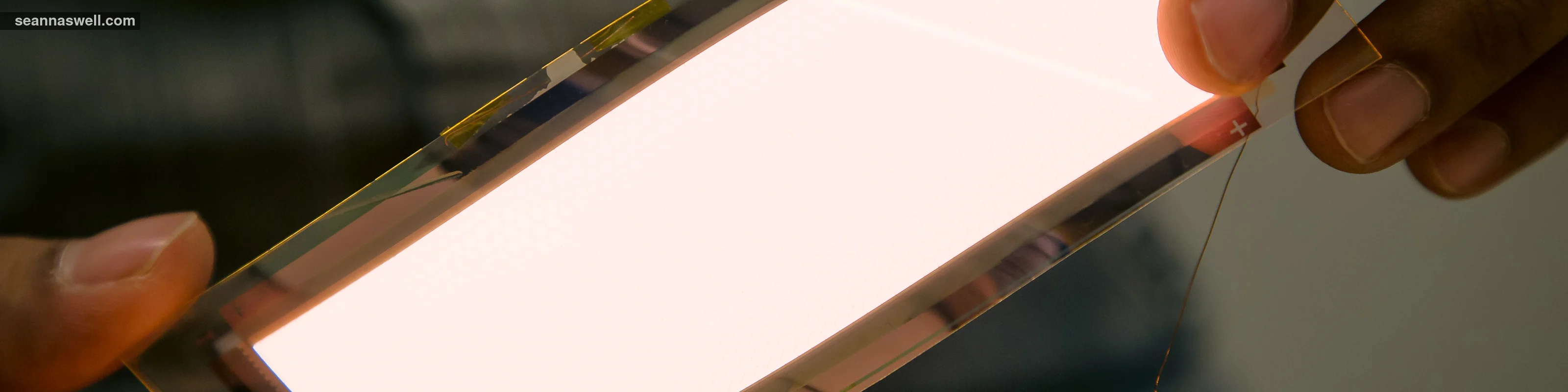

OLED Lighting

Starting in the late 1990's I designed, programmed and facilitated the installation of lighting control systems for high-end residential clients, working alongside architects and lighting designers to create beautiful lighting for their homes. That background made me pay attention when OLED solid-state lighting emerged around 15 years ago, as it represented everything lighting should be: efficient, elegant, and human-centric.

So, a few years ago when I went looking for OLED lighting fixtures for a personal project, I was surprised to find almost nothing available. Then, a few months ago I looked again as some lighting fixtures in the bus needed replacing, and there were even less options. Out of desperation, a search for flicker free LED dimmers also turned up almost no options, at which point I started asking why.

After months of research, I found the answer: the industry is stuck using expensive, wasteful vacuum deposition methods designed for displays, not lighting. Therefore, OLED lighting panels are expensive to produce, and when combined with the decreasing cost of LED lights, made it difficult for OLED to survive.

However, there is a solution... What started as research has led to designing a commercial scale OLED manufacturing venture, bringing sustainable, domestically-produced solid-state lighting to market.

More coming soon...

A few reasons OLED lighting is a compelling alternative to LED:

Health & Comfort

- Naturally low blue light content - better for circadian rhythm and sleep quality

- Zero flicker - reduces eye strain, headaches, and visual stress

- Soft, diffuse light quality mimics natural daylight without harsh glare

Energy & Efficiency

- Lower power consumption than LED for equivalent light output

- Higher efficacy potential as the technology matures

- Cool operation - minimal heat generation

Design & Installation

- No heat sinks required - enables ultra-slim form factors

- No diffusers needed - the entire panel surface emits light uniformly

- Simpler housing and mounting systems

- Flexible form factors possible (depending on substrate)

Additional Benefits

- Mercury-free and more environmentally friendly

- Eliminates rare-earth phosphor dependency

- Potential for transparent/semi-transparent applications

- Eliminates reliance on existing LED supply chains (important for defense)